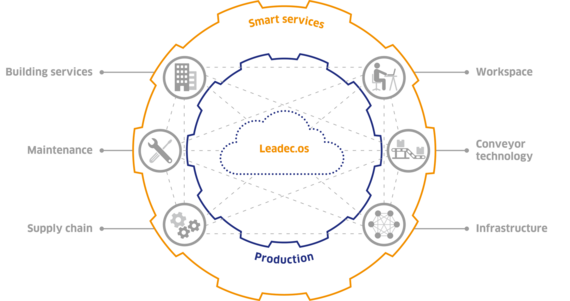

Leadec.os – the digital business platform

Leadec.os offers an end-to-end solution which digitizes all service processes across systems. This creates maximum transparency regarding planning and provision of all services.

Leadec.os offers an end-to-end solution which digitizes all service processes across systems. This creates maximum transparency regarding planning and provision of all services.

Leadec.os offers an end-to-end solution which digitizes all service processes across systems. This creates maximum transparency regarding planning and provision of all services. From the first offer to audit-proof documentation and invoicing. Customers can use the Leadec.os data with their own platforms and IT systems and thus continuously improve their production processes.

Markus Glaser-Gallion, CEO Leadec

Leadec.os captures, structures, evaluates and harmonizes data from different sources. This is the foundation for optimizing the processes in the factory concerned and to meet the requirements of the “factory of the future.” Because data is the basis of modern manufacturing. While manufacturing companies mainly rely on information from machines for this purpose, support services have so far mostly been considered separately. Thus, there is a lot of potential.

This is exactly where the cloud-based solution Leadec.os comes in: The platform seamlessly fits into the customers’ different digital ecosystems. Behind it is the Salesforce technology and comfortably creates an interface with existing systems. An own IoT Home Cloud, which Leadec operates to optimally connect to the industrial companies’ cloud environments, complements the new platform and makes the collaboration particularly efficient.

Via the easy-to-use customer portal, Leadec.os users access the different areas and can trigger orders as required – even on mobile devices including offline functionality for mobile service applications. The platform displays all assets, informs about maintenance needs and potential incidents and documents services provided in real time. The collected data also enables a comprehensive analysis across sites, for example of plant availability, and reveals potential for optimization.

At a large manufacturer of food packaging, the processes for technical facility management and technical cleaning are already running on Leadec.os. The employees there have access to the processes via a mobile device at any location in production – this shortens the processing time and ensures greater productivity. In the factory of a manufacturer of white goods Leadec.os shows its full flexibility. Here, the Leadec teams are mainly active on call for maintenance. Quick reaction, flexible service provision and a corresponding proof of performance via Leadec.os are decisive for success.